DEON high speed curing system

1/10 curing time of solder mask by super heated vapor

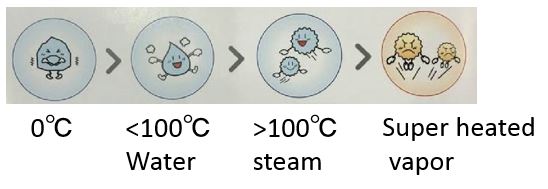

What is Super heated vapor?

Super heated vapor is high temperature vapor which is heated after the water reached to boiling point.

Why is it so fast to cure the ink?

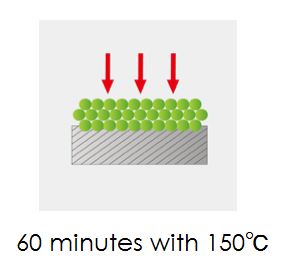

Conventional method of curing use oven to heat the ink, this method take time since the ink cured from outsite and gradually inside.

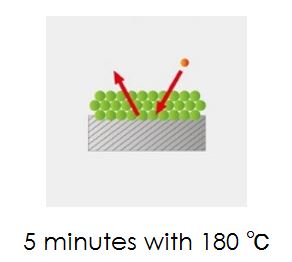

By super heated vapor, ink is cured inside and outside at same tme. This is available with the nano sized Super heated vapor.

Benefit of DEON solder mask curing system

1.Save big amount of resource and cost in your production (Nearly half compare to the conventional wicket line)

Short processing time reduce a lot of energy consumption and your resources. It will bring big impact for your production cost.

2. Improve quality with lower oxidization

Super heated vapor don't contain any oxigen, so that PCB never get the damage of oxidization. Less damage for PCB and improve the quality of your production.

3. Legend marking available, min. 3 minutes

It is also possible to cure legend marking, it takes around 3 minutes.

4. Short production line, 18m becomes only 5m. (*As one customer example)

One customer replace their curing line from 18m to 5m. Less spacing and quick curing.

Product line up

Stand alone box type

As for the solution of offline curing system

PCB size: W200 x H200mm to W610 x H510mm

Thickness: 0,2 to 2,4mm

Possible to cure solder mask in 5 minutes

Legend marking curing also available

Inline solution

Inline system for your production line. For the detailed specification, please feel free to contact to us.

PCB size: W200 x H200mm to W610 x H510mm

Thickness: 0,2 to 2,4mm

Possible to cure solder mask in 5 minutes

Legend marking curing also available

Cycle time: 7 seconds/panel as fastest, available with rack production

Possible to connect Developing process line

Automatic adjustment for different panel