Roll to roll both side plasma processing with high performance and productivity

| R220W | |

| Machine Dimension |

H: 1600mm |

| Weight | Appx. 3000kg |

| Power | 3 Phase 200V, 50kVA |

| Cooling water | Single system, difference between in/out over 0,1MPa, 50NL/min. |

| Compress air | 0,5 - 0,7 MPa 10NL/min. |

| Process gas | O2, Ar, CF4, N2, H2 |

| Other | Emmision duct |

| Process | Roll to Roll |

| Max. work size | Width 520mm x 200m roll (Custom available) |

| Process side | Double side |

| Function |

Improve Wettability |

| Application | Mass production |

- High speed and homogeneous processing by the plasma scan direct to the work.

- 600m width reactor specialized for the wide range processing.

- High performance for Ashing and other surface treatment.

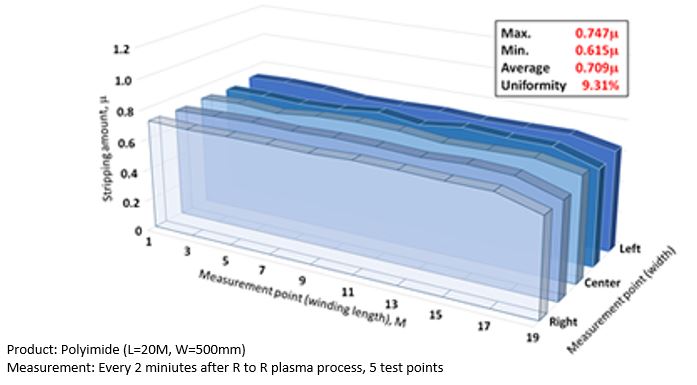

Example: Ashing of polyimide film

Result of the processing of Length 20m, width 500mm, thickness 0,05mm.

Material: Polyimide (Kapton®EN)

Average processing qty: 0,709m

Homogeneousness: ± 9,31%

High performance and homogeneousness to the direction of rolling, also the direction to plasma unit.

World top class performance by the Ashing rate and homogeneousness.